Home / T Type Strainers

Have A Question?

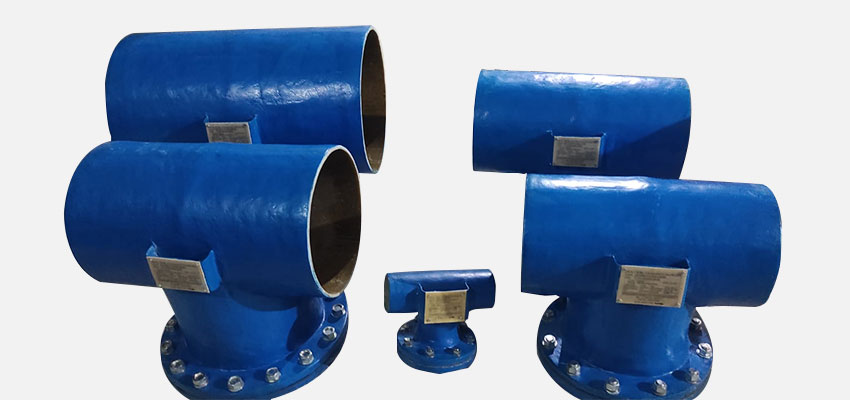

T strainers, also known as Tee strainers or T-strainers, are in-line basket strainers that are commonly used in pipelines to prevent damage to meters, pumps, check valves, flow meters, and other process equipment. T type Strainers in India are designed to remove particles from pipelines that require an integrated and accessible strainer to protect the fluid handling system. In addition, specially fitted micron masks and screens ensure optimal operating parameters. In addition, the T-type Strainers are designed to remove foreign objects from the pipeline. Standard T-type Strainers are made of carbon or stainless steel material. We can also supply T-type Strainers with almost any material. These filters include the production of chromium moly. Terminal connections and other accessories are available.

The T-type Strainer is a custom-made compact infuser. T type Strainers in Mumbai are made of pipes, plates, or equivalent standard T-pieces and WNRF flanges. The filter element is made of stainless steel perforated plates or wire mesh at the back with perforated plates. T type Strainers often use frame structures made of flat and round rods to support the wire mesh. T Type Strainers are a cheap solution to large nominal requirements for cavitation voltage. The T-type Strainers are equipped with either a screw cap or a quick-release lid to suit the application.

FRP T- type strainers are manufactured for filtering and filtering various liquids. These are made to hold solids of approximately several sizes. These are easily removable and easy to clean. These are made up of filter elements and filter covers. These are available in positive seals and can work well with strong curves. Advantages of FRP T- type strainers over other metals include:

If the strainer has a home screen, be aware of pressure drops. Additionally, if maximum efficiency is required, determine how long it will take the pressure drop to double the clean state. Additionally, when the pressure drop reaches an unacceptable value, close the line and follow the"screen removal procedure" above. Next, a pressure gauge is installed before and after the inline T type Strainers in Mumbai to show pressure loss due to blockage. Therefore, it can be used to determine when cleaning is needed.