Home / FRP Centrifugal Blowers

Have A Question?

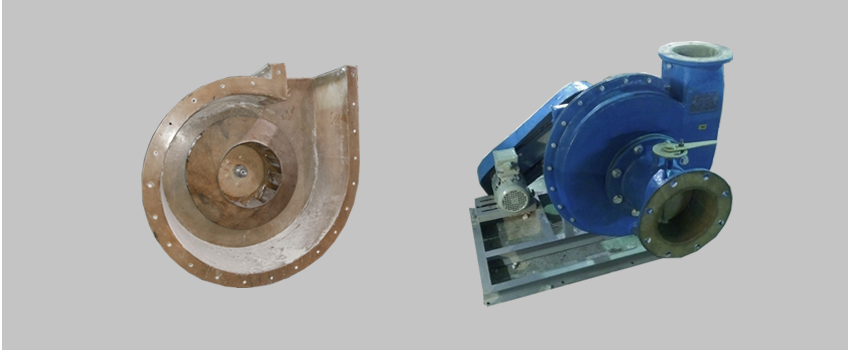

Centrifugal blowers are one of the most prevalent store-purchased solutions for exhaust gas extraction. The popularity of centrifugal blowers in exhaust systems is due to several important advantages. A centrifugal blower is a mechanical device that moves air or other gas in a direction at an angle with respect to the inflowing air. Centrifugal blowers often have a tube housing that directs outward air to a particular direction or heatsink. These blowers increase the speed and amount of airflow by rotating fans. Choosing the wrong impeller often results in increased energy consumption and higher levels of noise pollution without compromising efficiency. Fortunately, fibre-reinforced plastic blowers or FRP blowers are offered by FRP Centrifugal Blowers Manufacturer in India.

To obtain even higher power levels, manufacturers around the world are considering the use of fibreglass reinforced plastic blowers. These blowers produce higher intake and lift conditions with a more sophisticated design. Therefore, the overall efficiency is greatly improved. The improved aerodynamic design offers many of the benefits associated with FRP blowers, such as higher throughput and better quality.

Air defence- The aerodynamically designed impeller is housed in an FRP Centrifugal Blowers and is highly efficient, making it ideal for a wide range of applications.

Less weight- Compared to other types, the weight of FRP Centrifugal Blowers is slightly reduced. It improves durability, but it also extends the life of mechanical systems such as bearings, motors, and gearboxes.

Ratings and regulations- FRP Centrifugal Blowers require a light load-bearing system and motor ratings for the blower motor.

Low energy consumption- Minimal power consumption is required to operate the FRP Centrifugal Blowers. Compared to other metal blowers, this saves a lot of power.

Manufacturing- Composite manufacturing methods are used by FRP Centrifugal Blowers Manufacturer in Mumbai, such as standard casting, compression, and transfer casting. The result is an FRP Centrifugal Blowers with uniform dimensions and uniform quality impellers.

Noise pollution- The FRP Centrifugal Blowers greatly reduces mechanical noise and smoothes the flow of sound.

Life and durability- FRP Centrifugal Blowers are durable and have a long life due to their enhanced mechanical strength.

Corrosion resistance- Depending on the material used by the FRP Centrifugal Blowers Manufacturer in India, it is wear-resistant and corrosion-resistant.

Fire protection- Vibration-free operation is produced by the FRP Centrifugal Blowers and is, therefore, fire-resistant.

Centrifugal blowers are continuous-sized units designed with fast blades or impellers that rotate at approximately 15,000 rpm. Due to the high blade speed of FRP Centrifugal Blowers, they are widely used in industrial applications to carry large volumes of air at medium to low constant pressures. Compared to other types of blowers, FRP Centrifugal Blowers are capable of producing more pressure even at low speeds.

FRP Centrifugal Blowers Manufacturer in Mumbai offers FRP Centrifugal Blowers for a wide range of industries and for a variety of industrial processes, including vacuum applications and wastewater treatment. All the FRP Centrifugal blowers are manufactured according to the IS4894, ASTMD 4167, ISO 1940 Gr 6.3 standards to ensure quality and safety.

FRP centrifugal blowers play an important role in treating and exhausting poisonous and corrosive gases laden with vapours in various industries such as pharma, chemical, and other related industries. FRP centrifugal blowers can be customized as per the extraction needs of industries and plants. The technologically advanced design and software make FRP centrifugal blowers highly efficient and cost-effective.